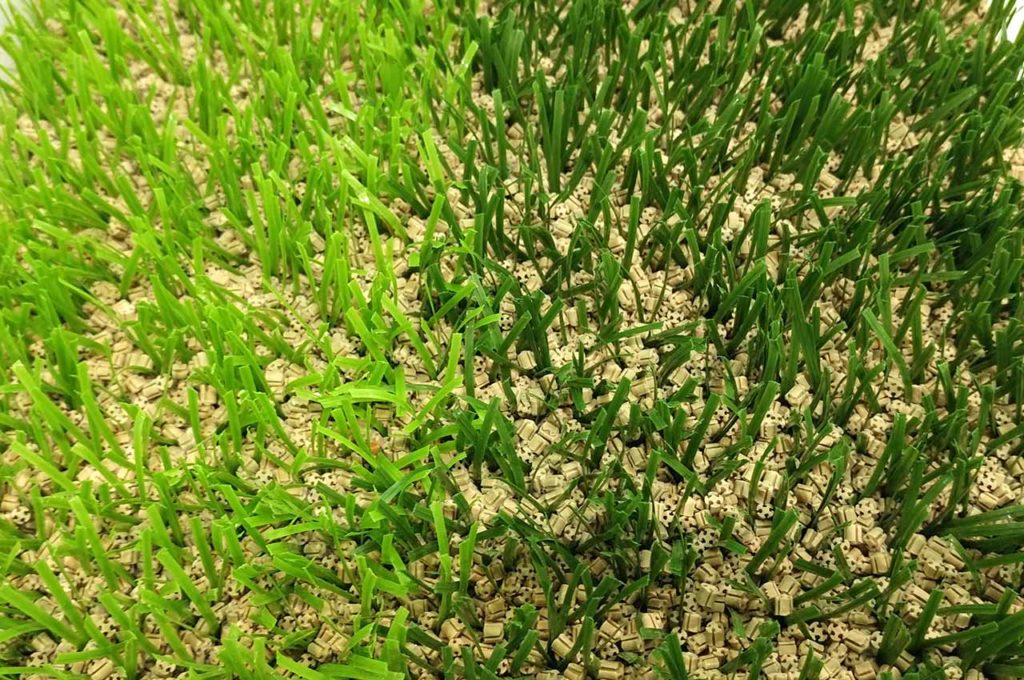

The infilling granule in the artificial grass system is an important part and plays a very important role.

In addition to protecting grass blades and stabilizing the grass system, it can also provide the sports performance required by the football grass fields, such as friction coefficient, cushioning performance, rotational resistance, etc.

These make the artificial turf lawn as much closer to the natural lawn. With the development of the industry, there are more and more types of artificial grass infilling granules.

The project owners have higher and higher requirements for football grass infilling materials. Nowadays, they pay more attention to environmental protection and health than to sports performance.

So far, the common types of infilling granules are quartz sand, SBR rubber granules, EPDM granules, TPE / TPO / PE granules and organic granules.

These products have their own advantages and disadvantages, which are briefly introduced below.

Quartz sand

As the most common infilling granule, quartz sand or silicon sand has obvious advantages and disadvantages.

The price is cheap, and you can buy it everywhere because of the large supply. Moreover, the water permeability is very good. It is not only easy to wear grass blades but also easy to scratch athletes’ skin during use, so don’t think about sliding and kneeling after scoring.

So far, when the artificial grass is filled with quartz sand, the upper layer is mostly infilled with other kinds of elastic infilling granules to ensure performance at the same time.

SBR rubber granules

SBR rubber granules are also traditional infilling materials, which are basically made of recycled waste tires.

With low price and cost, perfect elasticity and durability, and excellent UV resistance and weather resistance, SBR rubber granules are one of the largest infilling materials in the world.

Although there is no clear report in the world to point out whether SBR rubber granules are really harmful to the health of players, its uncontrollable sources and pungent smell, especially in hot weather in summer, make it difficult to associate it with the word ‘environmental protection’.

EPDM granules

EPDM (ethylene propylene diene monomer) granule was originally an elastomer granule used for athletic running track. However its excellent elastic performance is also very suitable for artificial grass infilling.

In recent years, it has been used as an ‘environmental protection substitute’ for SBR granules. It has no pungent smell, uniform particle size and good sports performance. Besides, EPDM granules can be made into the color you want. However, the UV resistance and aging resistance of EPDM are common, and the price is much more expensive than SBR granules. Moreover, qualified EPDM products have higher requirements for polymer content. The service life of EPDM granules with low polymer content is not only affected but also easy to harden. EPDM granules can be produced by original materials or recycled ones. This has resulted in negative reputation on the quality of EPDM granules in global market, which contractors should make a careful consideration.

TPE / TPO granules

TPE / TPO granules are thermoplastic elastomers. Their basic properties are basically the same as those of EPDM granules. They have no pungent smell, uniform granule size and customized colors. The difference is that TPE / TPO granules can also be recycable. Similarly, they have high price and cost, average weather resistance and require a minimum of polymer content. As a new artificial grass infilling product, There is not yet a large and stable supply in global market.

Organic granules

At present, there is also organic granules in the artificial turf infilling material market, which is composed of pure natural sawdust. It is with pure natural composition, good UV resistance, aging resistance and corrosion resistance, low density, no pungent smell and cooling performance. However, this product has poor sports performance, which is not only expensive, but also requires additional maintenance costs. Due to low density, it is easy to be washed and lost in heavy rain. It is a small market share at present.